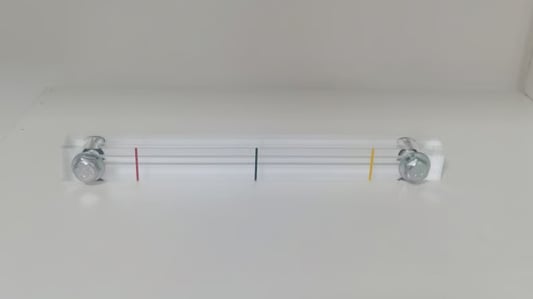

Introduction to Air compressor air filter AF1002The Air compressor air filter AF1002 is a vital component designed to enhance the lifespan and performance of air compressors. This specific air filter is engineered to trap contaminants such as dust, dirt, and oil particles that can damage the compressor or hinder its function. By maintaining clean air intake, the AF1002 ensures optimal efficiency and reliability in various industrial and commercial applications.Design and Construction FeaturesThe AF1002 air filter is crafted using high-grade materials that provide durability and effective particulate filtration. Its multi-layered filtration medium is capable of capturing fine contaminants down to microns, preventing the ingress of harmful debris. The filter housing is typically constructed from corrosion-resistant materials, offering longevity even in demanding environments.Compatibility and Application ScopeThis air compressor air filter model AF1002 is compatible with a wide range of compressor brands and models, making it a versatile option for many users. It is widely employed in industries such as manufacturing, automotive repair, and pneumatic tool operation, ensuring clean air supply and safeguarding equipment across diverse work settings.Installation and Maintenance SimplicityOne of the advantages of the AF1002 filter is its straightforward installation process, usually requiring minimal tools and technical expertise. Maintenance involves regular inspection and timely replacement to maintain air quality and compressor efficiency. Users benefit from clear guidelines on upkeep, helping to extend compressor life and reduce downtime.Performance Impact and Efficiency EnhancementInstalling the Air compressor air filter AF1002 leads to noticeable improvements in compressor performance. By filtering out impurities, the device prevents internal wear and reduces energy consumption. This efficiency gain translates to cost savings and higher productivity for businesses relying on air-powered tools and systems.Cost-Effectiveness and Economic BenefitsThe AF1002 air filter offers excellent value for its cost, combining effective filtration with a reasonable price point. Its longevity and protective function contribute to lower maintenance and repair expenses for air compressors. Investing in this filter can result in fewer breakdowns and improved machine uptime, making it economically beneficial.Environmental Advantages of Using AF1002Using a quality air compressor air filter like the AF1002 supports environmentally responsible practices by minimizing pollutant emissions. Cleaner air intake reduces compressor oil contamination and the release of harmful particles into the workspace, contributing to safer and healthier working conditions.Technical Specifications BreakdownThe AF1002 filter is characterized by specific dimensions, filtration ratings, and flow capacity tailored to optimize compressor performance. These specifications ensure compatibility and functional excellence. The filter typically handles high air pressures and flow rates, making it suitable for heavy-duty operations.Customer Reviews and Industry FeedbackUsers of the Air compressor air filter AF1002 have reported increased compressor reliability and improved air quality after installation. Industry professionals praise its robust design and effectiveness in demanding applications. Positive testimonials underscore the importance of quality filtration in maintaining equipment health.Where to Purchase and Warranty InformationThe AF1002 air filter is widely available through authorized dealers and online marketplaces specializing in industrial equipment parts. Buyers should verify warranty terms, which generally cover manufacturing defects for a specific period, assuring product reliability. Choosing genuine parts is critical for ensuring performance and protection.Quote Inquirycontact us