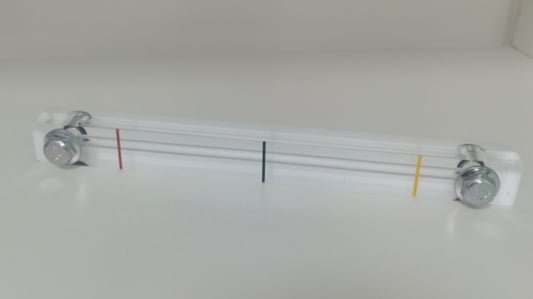

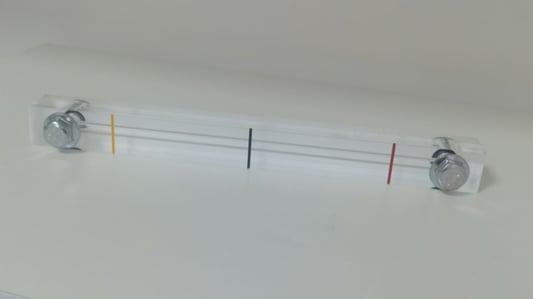

FunctionalityA level gauge is designed to accurately measure the level of liquid in a tank or vessel, providing a numerical reading for precise monitoring. On the other hand, a sight glass is a transparent window that allows visual inspection of the liquid level without the need for instrumentation.Material of ConstructionLevel gauges are typically made of metal or plastic materials that are corrosion-resistant and durable. In contrast, sight glasses are primarily constructed from glass or plastic, allowing for a clear view of the liquid inside the tank.Accuracy and PrecisionLevel gauges provide accurate readings of the liquid level, often with high precision to ensure reliable monitoring. Sight glasses, on the other hand, offer a general indication of the liquid level but may not provide the same level of accuracy as level gauges.Installation and MaintenanceLevel gauges require proper installation and periodic calibration to maintain their accuracy and functionality. Sight glasses are relatively easy to install and require minimal maintenance, making them a convenient option for visual liquid level inspection.Pressure and Temperature ResistanceLevel gauges are designed to withstand varying pressure and temperature conditions, making them suitable for use in demanding industrial environments. Sight glasses may have limitations in terms of pressure and temperature resistance, depending on the material of construction.Application FlexibilityLevel gauges are versatile tools that can be used in a wide range of industries, including chemical processing, oil and gas, and food and beverage. Sight glasses are commonly used in applications where visual inspection of liquid levels is sufficient, such as laboratory settings or small-scale operations.Visibility and ClarityLevel gauges provide a clear numerical display of the liquid level, allowing for easy monitoring and precise measurement. Sight glasses offer a direct line of sight to the liquid inside the tank, providing visual confirmation of the level without the need for interpretation.Cost and InvestmentLevel gauges may have a higher initial investment cost due to their precision measurement capabilities and specialized design. Sight glasses are generally more cost-effective and simpler in design, making them a budget-friendly option for basic liquid level monitoring.Safety and ReliabilityLevel gauges are engineered to meet industry safety standards and regulations to ensure reliable and accurate monitoring of liquid levels. Sight glasses, while effective for visual inspection, may not offer the same level of safety features as level gauges in hazardous or critical applications.Integration with Control SystemsLevel gauges are often equipped with advanced technology for integration with control systems, allowing for real-time monitoring and automated alerts for level fluctuations. Sight glasses are standalone components that provide manual visual inspection and do not have built-in control system integration capabilities.Quote InquiryContact us!