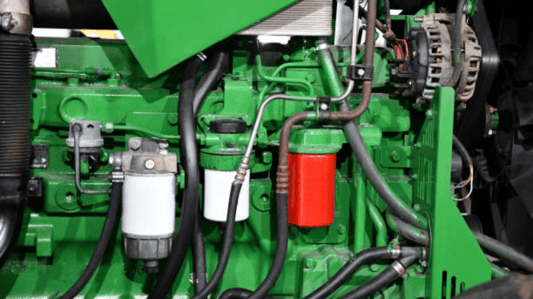

What is a hydraulic line filter?In industrial equipment, hydraulic line filters are crucial components that help maintain the cleanliness of the hydraulic system. These filters are designed to remove contaminants such as dirt, metal particles, and other debris from the hydraulic fluid, ensuring smooth operation of the machinery.Benefits of Using Hydraulic Line FiltersThe use of hydraulic line filters offers several benefits to industrial equipment. By effectively removing contaminants from the hydraulic fluid, these filters help prevent damage to the system components, extend the lifespan of the equipment, and improve overall system performance.Types of Hydraulic Line FiltersThere are different types of hydraulic line filters available, including in-line filters, cartridge filters, and spin-on filters. Each type has its own unique design and filtration capabilities, allowing users to choose the best option for their specific needs.How Hydraulic Line Filters WorkHydraulic line filters operate by trapping contaminants as the hydraulic fluid passes through the filter media. The filter media is designed to capture particles of various sizes, ensuring that only clean fluid flows through the system and prevents damage to the equipment.Importance of Regular MaintenanceTo ensure the effectiveness of hydraulic line filters, regular maintenance is essential. It is recommended to monitor the pressure drop across the filter, inspect the filter elements for any signs of wear or damage, and replace the filter as needed to keep the hydraulic system operating smoothly.Choosing the Right Hydraulic Line FilterWhen selecting a hydraulic line filter for industrial equipment, it is important to consider factors such as the flow rate, pressure rating, filtration efficiency, and compatibility with the hydraulic fluid used in the system. Consulting with a knowledgeable supplier can help ensure the right filter is chosen.Common Contaminants RemovedHydraulic line filters are effective in removing a variety of contaminants from the hydraulic fluid, including dirt, rust, metal shavings, and other particles that can cause damage to the system components. By keeping the fluid clean, these filters help maintain the integrity of the equipment.Signs of a Clogged FilterOne common issue with hydraulic line filters is clogging, which can restrict the flow of hydraulic fluid and lead to system malfunction. Signs of a clogged filter include increased pressure drop, reduced system efficiency, and unusual noises coming from the equipment.Replacing Hydraulic Line FiltersIt is important to follow the manufacturer's recommendations for replacing hydraulic line filters to ensure optimal performance of the equipment. Regularly changing the filters will help prevent system damage, improve efficiency, and extend the lifespan of the hydraulic components.ConclusionIn conclusion, hydraulic line filters play a critical role in maintaining the cleanliness and efficiency of industrial equipment. By choosing the right filter, performing regular maintenance, and replacing filters as needed, users can ensure the smooth operation and longevity of their hydraulic systems.Quote InquiryContact us!