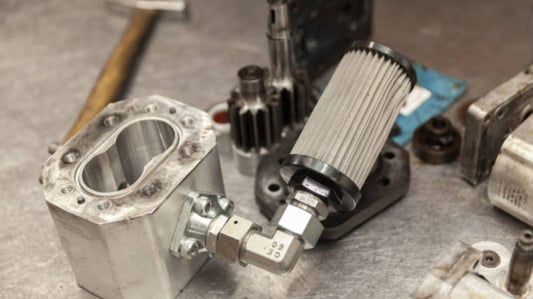

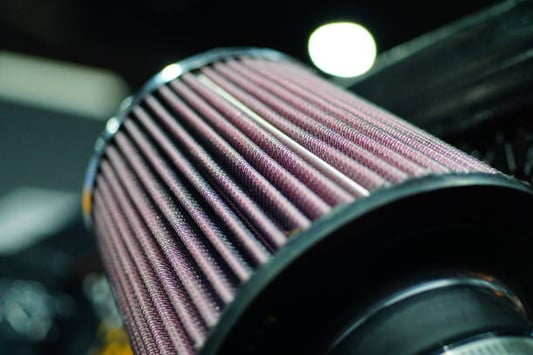

Understanding the Hydraulic Suction FilterThe hydraulic system is one of the most vital components of heavy machinery, and it needs regular maintenance to keep it running smoothly. One of the most crucial parts of the hydraulic system is the hydraulic suction filter. It filters out any contaminants in the oil so that they do not damage the hydraulic components. In this article, we will discuss the location of the hydraulic suction filter.The Location of the Hydraulic Suction FilterThe hydraulic suction filter is typically located inside the hydraulic reservoir. The reservoir is usually situated in the lower part of the machine and is accessible from outside. The location of the hydraulic suction filter may differ depending on the make and model of the machine.Locating the Hydraulic ReservoirTo find the hydraulic suction filter, you first need to locate the hydraulic reservoir. The hydraulic reservoir is typically a large cylindrical container made of metal or plastic. It is usually located at the base of the machine and can be accessed from the outside.Opening the Hydraulic ReservoirOnce you have located the hydraulic reservoir, the next step is to open it. This may involve removing any bolts, screws or other fasteners that hold the reservoir cover in place. Some machines may have a latch or a hinge that allows for easier access.Finding the FilterAfter opening the hydraulic reservoir, you should be able to see the hydraulic suction filter. The filter is usually located close to the pump inlet or the fluid return line. It may be enclosed in a plastic or metal housing. Make sure to check your machine's manual if you can't locate the filter easily.The Importance of Maintaining the Hydraulic Suction FilterThe hydraulic suction filter is an essential component of the hydraulic system, and its maintenance is critical to the longevity of the system. A clogged or dirty filter can cause significant damage to the hydraulic system and lead to costly repairs. Regular replacement or cleaning of the filter is highly recommended.How Often Should You Replace the Hydraulic Suction Filter?The recommended replacement interval for the hydraulic suction filter varies depending on the make and model of the machine. It is generally recommended that you change the filter every six months or after every 500 hours of use. However, it is essential to check your machine's manual for specific recommendations.The Benefits of Regular Filter MaintenanceRegular maintenance of the hydraulic suction filter is essential to keep the hydraulic system running smoothly. It helps to prevent downtime and costly repairs. A clean filter also ensures that the hydraulic system operates at maximum efficiency, reducing fuel consumption and increasing performance.ConclusionThe hydraulic suction filter is a vital component of the hydraulic system, and its maintenance is critical to the longevity of the machine. By following the steps outlined in this article, you can easily locate the hydraulic suction filter and ensure that it is properly maintained. Don't forget to refer to your machine's manual for specific recommendations.hydraulic suction filter, hydraulic reservoir, filter maintenance, heavy machinery, hydraulic systemWhere is the hydraulic suction filter located?? A Complete GuideLearn how to locate and maintain the hydraulic suction filter to keep your heavy machinery running smoothly. Discover the benefits of regular filter maintenance and the importance of keeping your hydraulic system free from contaminants.Quote InquiryContact us!