Why a high pressure fluid filter is Essential for Industrial ApplicationsIndustrial applications often involve the use of high pressure fluid systems that require effective filtration to ensure optimal performance and prevent damage to equipment. A high pressure fluid filter plays a critical role in these applications by removing contaminants and maintaining the purity of the fluids. In this article, we will explore the various aspects and benefits of using a high pressure fluid filter.1. Understanding High Pressure Fluid SystemsIn industrial settings, high pressure fluid systems are commonly used for a wide range of applications, such as hydraulic systems, lubrication systems, cooling systems, and more. These systems operate under immense pressure, which can range from a few hundred to several thousand pounds per square inch (psi). The fluids used in these systems can include oils, water, chemicals, and gases.2. The Role of a High Pressure Fluid FilterA high pressure fluid filter is designed to remove impurities, contaminants, and solid particles from the fluid stream. It ensures that the fluid circulating in the system remains clean and free from harmful substances that can cause damage to equipment, reduce efficiency, or compromise the quality of the end product. By effectively filtering the fluid, a high pressure fluid filter helps to prolong the lifespan of the system components and optimize performance.3. Types of High Pressure Fluid FiltersThere are various types of high pressure fluid filters available in the market, each designed for specific applications and operating conditions. Some common types include cartridge filters, bag filters, magnetic filters, and depth filters. Cartridge filters are widely used due to their versatility and efficiency in removing both large and small particles. Bag filters are suitable for higher flow rates, while magnetic filters are effective in capturing ferrous contaminants. Depth filters, on the other hand, offer a greater capacity for retaining particles.4. Benefits of Using a High Pressure Fluid FilterUsing a high pressure fluid filter offers several advantages in industrial applications:Improved Equipment Performance: By removing contaminants, the filter ensures smooth operation and reduces the risk of equipment failure.Enhanced Product Quality: Clean fluids prevent product contamination, resulting in higher quality end products.Extended Equipment Lifespan: Filtering the fluid helps to prevent wear and tear on system components, thus prolonging their lifespan.Reduced Maintenance Costs: By keeping the fluid clean, the filter reduces the need for frequent maintenance and equipment repairs.Increased Efficiency: Cleaner fluids allow for more efficient transfer of energy, leading to improved overall system efficiency.5. Factors to Consider When Choosing a High Pressure Fluid FilterWhen selecting a high pressure fluid filter for your industrial application, it is important to consider several factors:Operating Pressure: Ensure that the filter is capable of handling the maximum pressure of your system.Flow Rate: Select a filter with an appropriate flow rate to meet the demands of your application.Filtration Efficiency: Look for filters with a high filtration efficiency to effectively remove contaminants.Filter Material: Consider the compatibility of the filter material with the fluid being used in your system.Maintenance Requirements: Assess the ease of maintenance and replacement of filter elements.6. Installation and Maintenance of High Pressure Fluid FiltersProper installation and regular maintenance are crucial for ensuring the optimal performance of high pressure fluid filters. Here are some key considerations:Follow Manufacturer's Guidelines: Adhere to the installation instructions provided by the filter manufacturer to ensure proper functioning.Monitor Pressure Drop: Regularly check the pressure drop across the filter and clean or replace the filter elements as necessary.Inspect Seals and O-rings: Ensure that all seals and O-rings are in good condition to prevent leakage.Schedule Routine Maintenance: Establish a maintenance schedule to clean or replace filter elements at recommended intervals.7. Applications of High Pressure Fluid FiltersHigh pressure fluid filters find applications in various industries, including:ManufacturingAutomotiveOil and GasChemical ProcessingPharmaceuticalPower Generation8. Industry Standards and RegulationsSeveral industry standards and regulations govern the use of high pressure fluid filters to ensure safety and performance. It is essential to comply with these standards, such as those set by organizations like the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO).9. The Future of High Pressure Fluid FiltersAs technology continues to advance, high pressure fluid filters are also evolving to meet the ever-increasing demands of industrial applications. The future of these filters may involve advancements in filtration materials, improved efficiency, and integration with smart monitoring systems for predictive maintenance.10. ConclusionHigh pressure fluid filters play a crucial role in maintaining the cleanliness and integrity of fluids used in industrial applications. By effectively removing contaminants and impurities, these filters ensure optimal performance, increased equipment lifespan, and enhanced product quality. When selecting a high pressure fluid filter, consider factors such as operating pressure, flow rate, filtration efficiency, and maintenance requirements. By following proper installation and maintenance practices, industries can reap the benefits of utilizing high pressure fluid filters while complying with industry standards.Quote InquiryContact us!

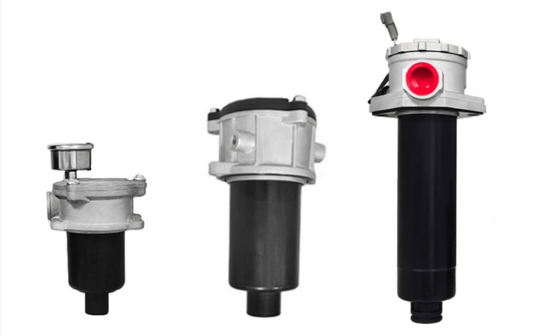

08. April, 2024