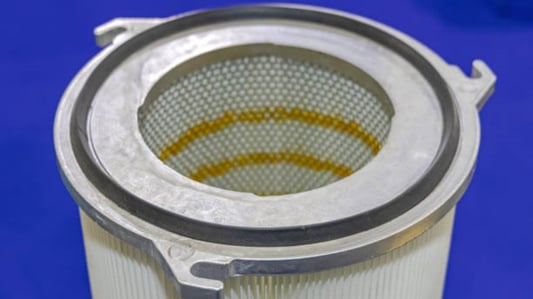

Hydraulic filters are essential components in hydraulic systems, ensuring that fluid remains clean and free of contaminants that could cause damage or reduce system performance. The technical requirements for hydraulic filters are stringent to ensure they effectively perform their function. Here are some key technical requirements:Filtration Efficiency: Filters must be capable of removing particles of a certain size from the hydraulic fluid. This is often measured by beta ratio (β ratio), which compares the number of particles upstream and downstream of the filter. Higher beta ratios indicate better filtration efficiency.Flow Rate Capacity of hydraulic filters: The filter must be able to handle the maximum flow rate of the hydraulic system without significant pressure drop. This ensures minimal impact on system performance.Pressure Ratingof hydraulic filters: The filter must withstand the maximum operating pressure of the hydraulic system, including any potential pressure spikes.Temperature Resistance: Hydraulic systems can operate at high temperatures, so the filter materials must be able to withstand these conditions without degrading.Compatibility with Hydraulic Fluids: The filter materials should not react chemically with the hydraulic fluid, which could lead to degradation of the filter or contamination of the fluid.Durability and Longevity of hydraulic filters: Filters should be made from durable materials that can withstand continuous operation over long periods without significant wear or degradation.Replacement Indicators: Some advanced filters come with indicators or sensors that signal when it's time for a replacement, helping to prevent system failure due to clogged or ineffective filters.Installation Requirements: The filter must fit properly into the hydraulic system, adhering to specific mounting dimensions and interfaces.Maintenance and Serviceability of hydraulic filters: Filters should be designed for easy maintenance and replacement to minimize downtime and operational disruptions.Environmental Considerations: In some applications, environmental regulations may require the use of filters that minimize waste or emissions during manufacturing, use, and disposal.By meeting these technical requirements, hydraulic filters help maintain the reliability and efficiency of hydraulic systems, extending their service life and reducing maintenance costs.Quote InquiryContact us!