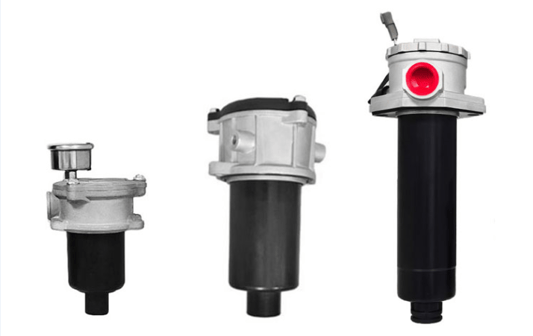

What is a High Filter and What Does it Do?A high filter is a device that is used to remove impurities from a liquid or gas. The filter consists of a porous material that allows the liquid or gas to pass through, while trapping any impurities.1. The Purpose of a High FilterThe main purpose of a high filter is to remove unwanted contaminants from the liquid or gas that it is filtering. These impurities can include particles, debris, dust, and other foreign materials that can harm the system or the end product.2. How Does a High Filter Work?A high filter works by forcing liquid or gas through a filtration medium that traps the impurities and allows the clean liquid or gas to pass through. The medium can be made of a variety of materials, including paper, mesh, ceramics, or plastics. The choice of medium depends on the application and the impurities being filtered.3. The Benefits of Using a High FilterUsing a high filter can have several benefits for different industries. For example, in the food and beverage industry, high filters can help remove contaminants from the product, ensuring a safe and hygienic product for consumption. In the pharmaceutical industry, high filters can help maintain the purity of drugs and prevent contamination. Overall, using a high filter can save money and time in the long run by preventing damage to equipment and reducing downtime.4. Types of High FiltersThere are several types of high filters that are used in different applications. Some of the most common are air filters, oil filters, fuel filters, and water filters. Air filters are used to remove dust and particles from the air, while oil filters remove impurities from oil in engines and machines. Fuel filters are used to remove contaminants from gasoline or diesel fuel, and water filters are used to purify the water used for drinking or industrial processes.5. Maintenance of a High FilterProper maintenance is crucial for the correct operation of a high filter. Regular cleaning and replacement of the filter medium is essential to ensure that the filter continues to work efficiently. The frequency of maintenance depends on the application and the level of contamination in the liquid or gas.6. The Importance of Choosing the Right High FilterChoosing the right high filter depends on the application and the type of impurities that need to be filtered. Several factors need to be considered, such as the size of the contaminants, the flow rate of the liquid or gas, and the temperature and pressure of the system. Using the wrong filter can cause damage to the system and lead to contamination.7. Common Filter Ratings and TerminologyFilter ratings and terminology can be confusing for those unfamiliar with high filters. Some of the most common terms include micron rating, nominal filter rating, absolute filter rating, and beta ratio. The micron rating is the size of the smallest particle that the filter can trap, while the nominal filter rating and absolute filter rating refer to the percentage of particles that the filter can remove. The beta ratio refers to the ratio of particles that pass through the filter to the particles that are trapped.8. Challenges of High Filter OperationHigh filter operation can face several challenges. One of the most common is clogging, where the filter medium becomes fully saturated and can no longer trap particles. Clogging can reduce the flow rate or cause damage to the filter. Another challenge is the formation of biofilms or other types of contaminants on the filter medium, which can reduce its effectiveness.9. Tips for Choosing the Right High FilterHere are some tips for choosing the right high filter:Consider the application requirements and the impurities to be filteredChoose the appropriate filter medium and size for the flow rate and pressure of the systemConsider the required maintenance and replacement intervalsConsult with experts or manufacturers to ensure the best fit for the application10. ConclusionHigh filters have become essential in different industries, from food and beverage to pharmaceutical and automotive. They provide a way to remove unwanted contaminants from liquids and gases, ensuring that the end product is safe, pure, and efficient. Proper maintenance and choosing the right filter are crucial for the efficient operation of high filters and the prevention of damage to the system.Quote InquiryContact us!