Wireless level monitoring refers to the use of wireless sensors and communication systems to measure and track the level of liquids or solids within tanks, silos, or reservoirs. This technology eliminates the need for manual readings and hardwired connections, allowing real-time data transmission over wireless networks. It is becoming an essential tool in various industries seeking efficient and accurate level control solutions.

Advantages of Wireless Level Monitoring over Traditional Systems

One major benefit of wireless level monitoring is its ease of installation, especially in remote or hard-to-access locations, where running cables is impractical or costly. Unlike traditional wired systems, wireless setups reduce infrastructure expenses and minimize downtime during installation. Moreover, wireless systems offer enhanced flexibility, scalable deployment, and easier maintenance.

Key Components of Wireless Level Monitoring Systems

A typical wireless level monitoring setup includes sensors (ultrasonic, radar, or capacitive), transmitters, gateways, and a central monitoring interface. Sensors detect the fluid or solid level and send data wirelessly to gateways, which relay information to cloud-based or on-premise control systems. The integration of IoT devices enables seamless data aggregation and analytics.

Applications Across Various Industries

Wireless level monitoring finds applications in industries such as water and wastewater management, oil and gas, chemical processing, food and beverage, and agriculture. For example, in oil & gas, it helps ensure safe storage by continuously tracking tank levels and preventing overflows. In agriculture, it aids irrigation management by accurately monitoring water reservoirs.

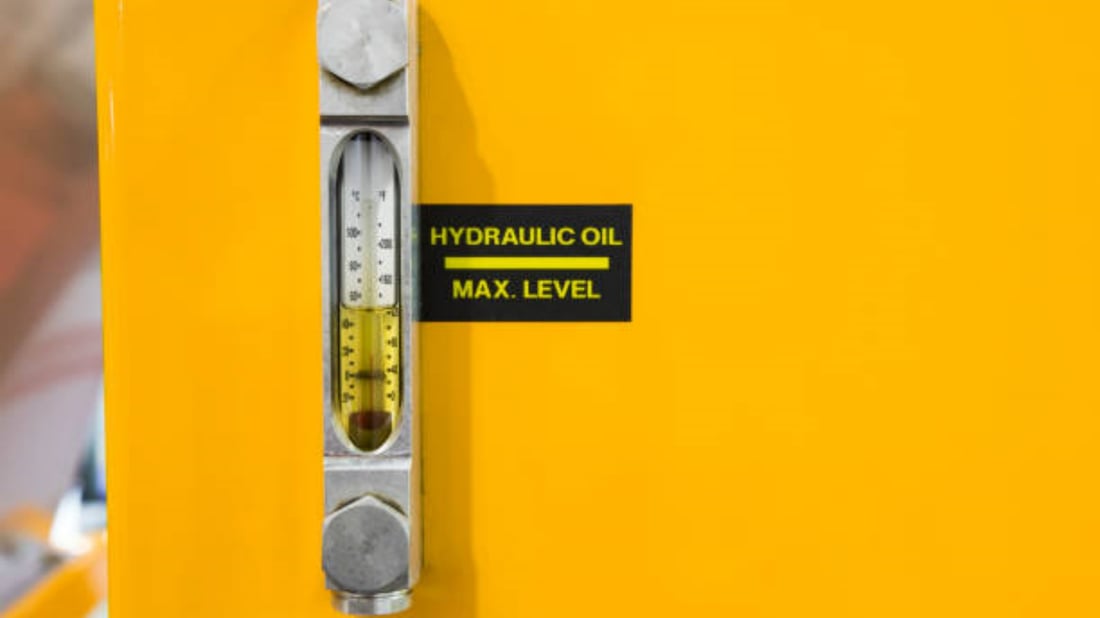

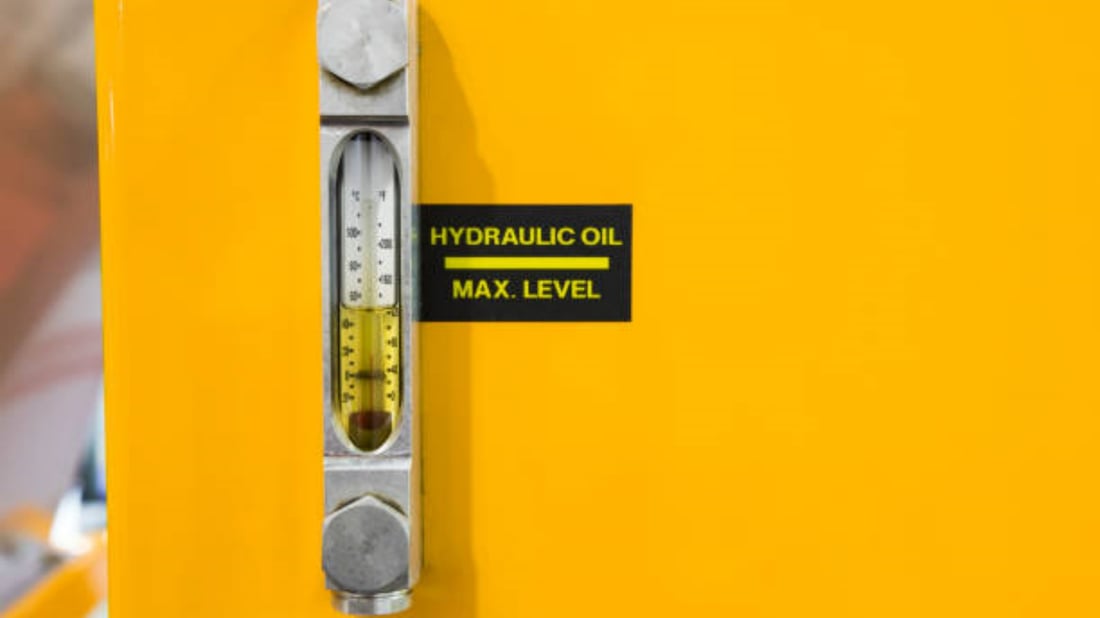

Improving Safety with Wireless Level Monitoring

In hazardous environments, minimizing human intervention is critical. Wireless level monitoring enhances workplace safety by providing remote access to tank and silo data, reducing the need for manual inspections and potential exposure to dangerous substances. It also helps detect leaks or abnormal conditions promptly, preventing accidents and environmental harm.

Cost Efficiency and ROI Benefits

Implementing wireless level monitoring reduces operational costs by cutting down labor-intensive manual checks and preventing costly downtime caused by overflows or equipment failure. The technology’s predictive maintenance capabilities also extend equipment lifespan and reduce emergency repairs, resulting in a strong return on investment.

Data Integration and IoT Compatibility

Modern wireless level monitoring systems support integration with IoT platforms, enabling data visualization, remote control, and advanced analytics. This connectivity allows operators to make data-driven decisions, optimize processes, and implement automated alerts. Such integration is crucial for smart factory initiatives and Industry 4.0 adoption.

Challenges and Considerations in Wireless Level Monitoring

Although wireless monitoring offers many benefits, it also presents challenges such as signal interference, data security concerns, and battery life limitations for wireless sensors. Selecting appropriate communication protocols (e.g., LoRaWAN, NB-IoT) and implementing robust cybersecurity measures are critical to overcoming these hurdles.

Emerging Trends and Future Outlook

The development of more energy-efficient sensors, AI-powered analytics, and enhanced wireless communication standards is driving the evolution of wireless level monitoring. Future systems will provide even greater accuracy, predictive maintenance capabilities, and seamless integration with smart infrastructure, making them indispensable to industrial operations.

Environmental Impact and Sustainability

Wireless level monitoring supports environmental sustainability by optimizing resource usage and minimizing waste. Accurate level measurements prevent spills and leaks that can damage ecosystems. The reduction in manual inspections also decreases carbon emissions associated with transportation and site visits, contributing to greener industrial practices.

Quote Inquiry

contact us