Understanding the Basics of a Level Gauge

A level gauge is a crucial instrument used in various industries to measure the level of liquids or gases in a tank or vessel. It provides real-time data to operators, allowing them to monitor and maintain optimal levels for efficient operations.

The Importance of Accurate Level Measurement

Accurate level measurement is essential for ensuring safety, preventing overflows, and optimizing processes. A level gauge helps operators make informed decisions and avert potential risks associated with inadequate levels of liquid or gas.

Types of Level Gauges

There are several types of level gauges available, including sight glass gauges, magnetic level gauges, ultrasonic level gauges, and radar level gauges. Each type has its unique features and applications, catering to different industry needs.

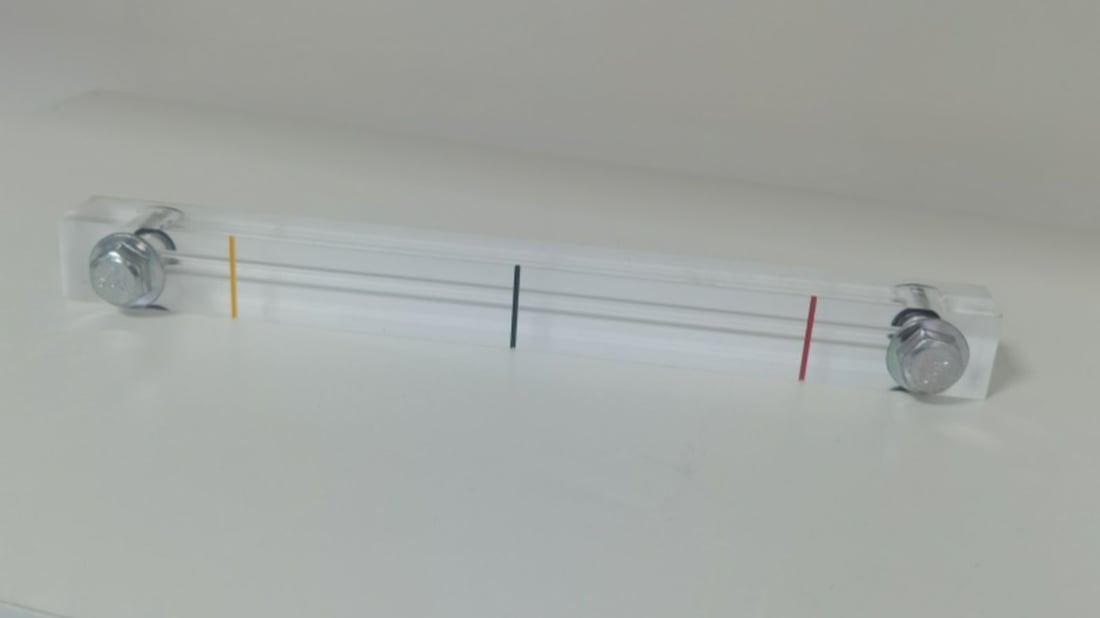

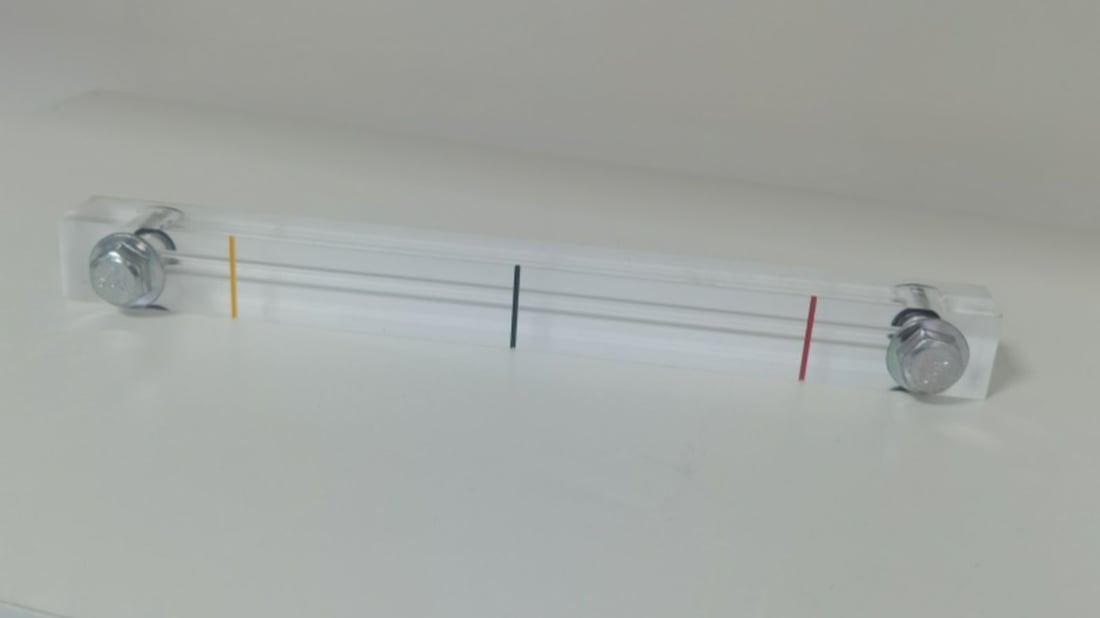

How Does a Level Gauge Work?

A level gauge typically consists of a transparent tube or chamber connected to the tank or vessel containing the liquid or gas. As the level changes, the fluid inside the gauge also adjusts, providing a visual indication of the current level.

Benefits of Using a Level Gauge

Using a level gauge offers numerous benefits, such as improved process control, reduced downtime, increased safety, and enhanced efficiency. It allows operators to monitor levels accurately and take corrective actions promptly.

Applications of Level Gauges

Level gauges are widely used in various industries, including oil and gas, chemical processing, pharmaceuticals, power generation, and food and beverage. They play a critical role in ensuring smooth operations and regulatory compliance.

Factors to Consider When Choosing a Level Gauge

When selecting a level gauge for a specific application, factors such as the type of fluid, operating conditions, accuracy requirements, and budget constraints need to be considered. It's essential to choose the right gauge that meets the unique needs of the process.

Installation and Maintenance of Level Gauges

Proper installation and regular maintenance are crucial for the optimal performance of level gauges. Routine checks, calibration, and cleaning are necessary to ensure accurate readings and prolong the lifespan of the gauge.

Challenges and Solutions in Level Gauging

Despite their benefits, level gauging systems face challenges such as contamination, corrosion, and calibration drift. Implementing preventive maintenance strategies, using advanced technologies, and training staff can help overcome these challenges.

Future Trends in Level Gauging Technology

Advancements in level gauging technology, such as wireless monitoring, IoT integration, and predictive analytics, are shaping the future of level gauges. These innovations enhance efficiency, reliability, and data accessibility in industrial applications.

Quote Inquiry

Contact us!