What is a hydraulic suction filter?

If you work in a hydraulic system, you understand how critical it is to maintain precise pressure levels and high levels of cleanliness. One of the key components that help make this possible is a Hydraulic Suction Filter. In this article, we will discuss what a hydraulic suction filter is and the vital role it plays in maintaining hydraulic systems.

What is a Hydraulic System?

Before diving into hydraulic suction filters, it's essential to understand what a hydraulic system is. A hydraulic system uses liquids, typically oil, to transfer force and energy from one point to another. These systems are in place to run essential machinery across various industries. Hydraulic components often need to move a high volume of fluid at high pressure and speed, which makes them vulnerable to wear and damage over time.

How Does a Hydraulic System work?

At the core of a hydraulic system is a hydraulic pump, which creates pressure in the system. The pressure created by the pump forces oil to flow through various components, including valves, actuators, and motors. When the oil reaches the other end of the system, the components release the pressure to produce movement or energy.

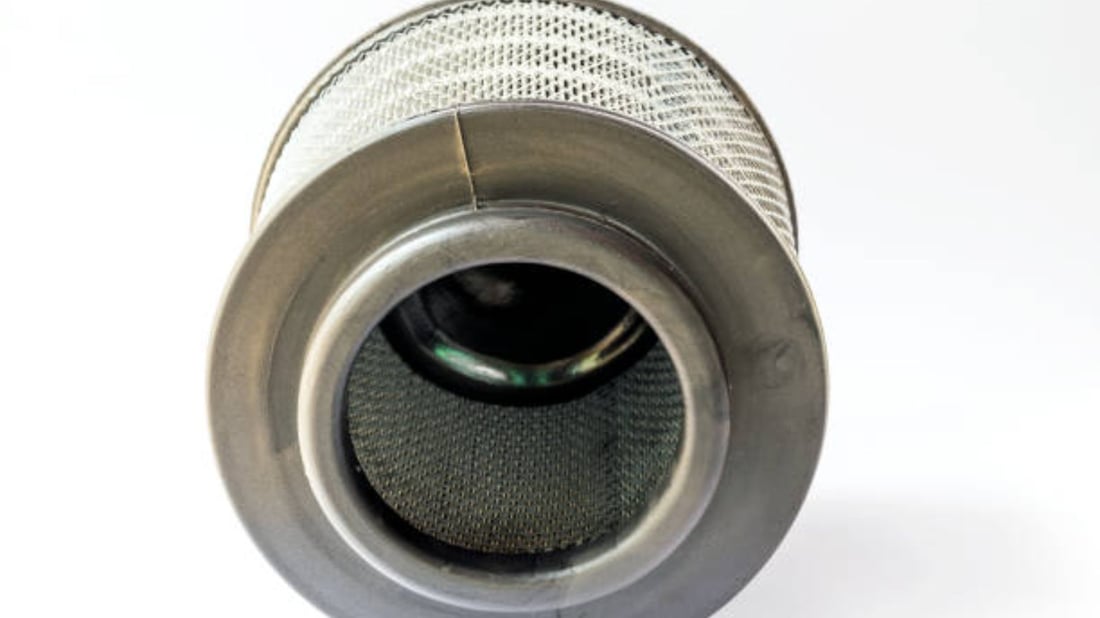

What is a Hydraulic Suction Filter?

A hydraulic suction filter is a filter element that is found in the suction line of a hydraulic system. It's there to protect the hydraulic components from contaminants in the fluid. The job of the suction filter is to capture any foreign particles that have entered the system that could cause damage to the pump and other hydraulic components. By removing these contaminants, the filter ensures that the fluid is clean and that the system can operate as intended.

How Does a Hydraulic Suction Filter Work?

Hydraulic suction filters work by trapping contaminants as the oil flows through the filter element. The filter element can capture particles of varying sizes, depending on its micron rating. The filter element is usually made up of a series of metal or plastic plates with holes or perforations in them. The hydraulic fluid travels through these plates and is filtered, capturing any contaminants along the way. After the oil has passed through the plates, it returns to the hydraulic system.

What are the Different Types of Hydraulic Suction Filters?

There are various types of hydraulic suction filters, including in-line, cartridge, and spin-on filters. In-line hydraulic suction filters are located directly in the hydraulic line. Cartridge filters are replaceable filter elements that are installed inside a filter housing. Spin-on filters are self-contained filters that screw into a filter head. Each type of filter has its unique benefits and drawbacks, and the selection depends on the needs of the hydraulic system and the application.

What are the Benefits of a Hydraulic Suction Filter?

There are several significant benefits of using a hydraulic suction filter. Firstly, they help protect the hydraulic system from wear and damage, improving reliability and reducing maintenance costs. Secondly, they help ensure the cleanliness of the hydraulic fluid, which is essential in preserving the system's efficiency and longevity. Thirdly, they help maintain the precise pressure levels required to make the system function correctly and safely.

How Often Should Hydraulic Suction Filters Be Replaced?

Hydraulic suction filters need to be replaced based on the manufacturer's recommendations and the operating conditions of the hydraulic system. In general, they should be replaced every 500 to 1000 hours of operation. However, if the system operates in harsh conditions, such as high temperatures or high levels of debris, the filter may need to be replaced more frequently. Regular inspections of the filter and oil analysis can help determine when a replacement is necessary.

What Happens If a Hydraulic Suction Filter is Not Used?

If a hydraulic suction filter is not used, the hydraulic system will be more vulnerable to damage and wear over time. Without a filter, contaminants such as dirt, debris, and metal particles can quickly enter the system, leading to damage and malfunctioning components. The cost of repairing and replacing damaged components can be far more expensive than the cost of maintaining hydraulic suction filters regularly.

Conclusion

Hydraulic suction filters are a critical component of a hydraulic system. They help maintain cleanliness, reduce wear and damage, and ensure that the system maintains the precise pressure levels required to function correctly. With proper maintenance, hydraulic suction filters can help preserve the efficiency and longevity of hydraulic systems across a range of industries.