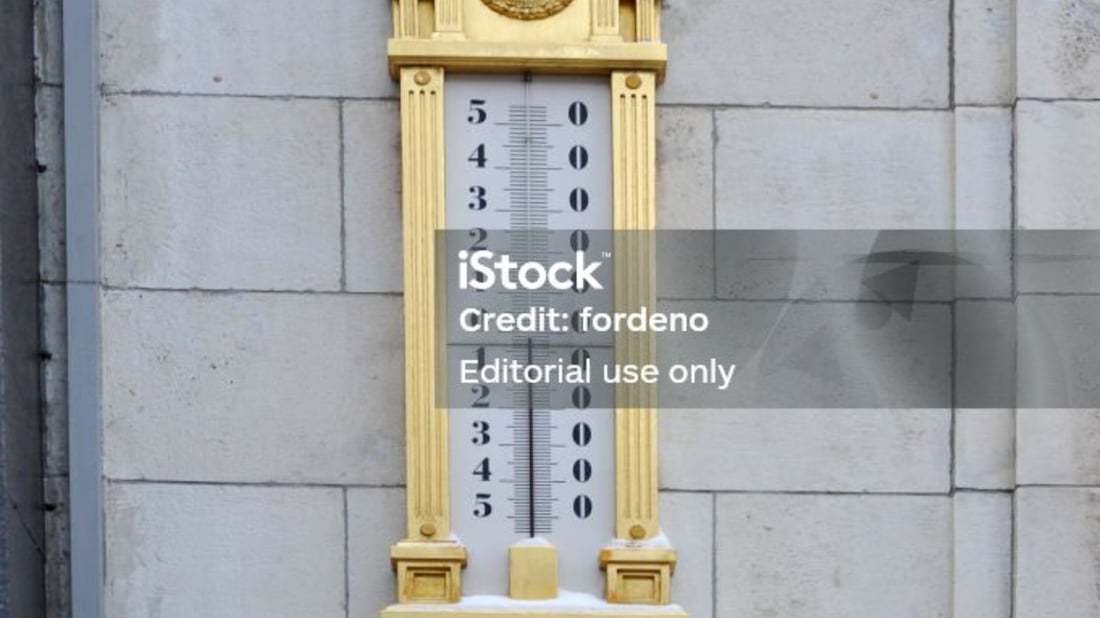

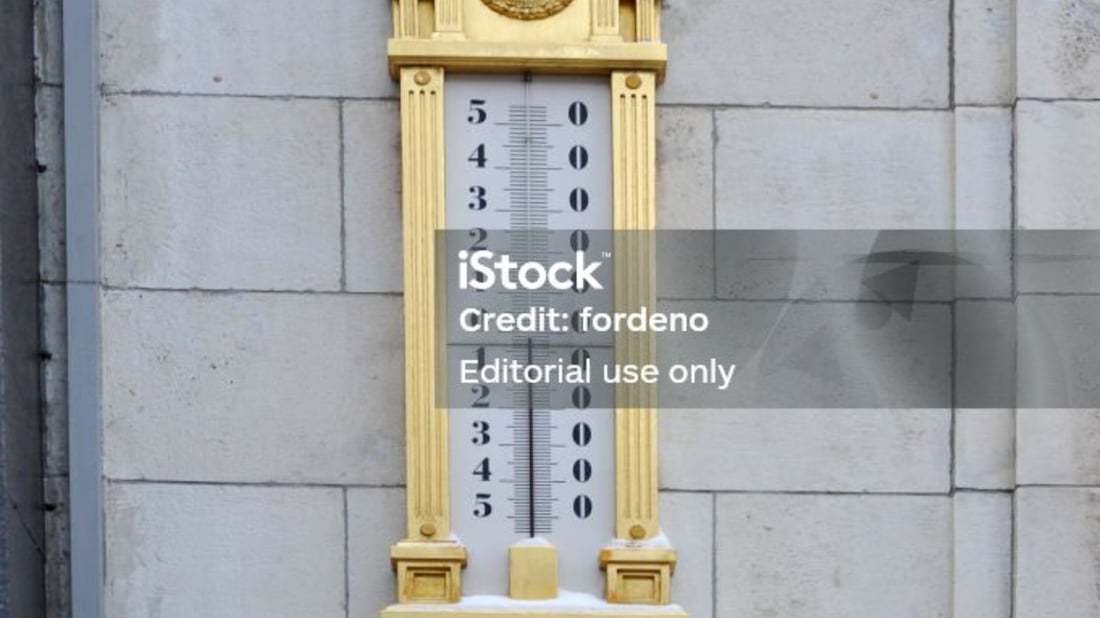

Types of Liquid Level Gauges

Liquid level gauges come in various types, including sight glass gauges, magnetic gauges, and float gauges. Each type operates differently but serves the same purpose of measuring the level of liquid in a tank or container.

How Does a Liquid Level Gauge Work?

A liquid level gauge typically consists of a sensor or probe that is inserted into the container to detect the level of the liquid. The sensor sends a signal to a display or indicator that shows the current level of the liquid. This allows users to monitor and control the liquid level easily.

Benefits of Using a Liquid Level Gauge

Liquid level gauges offer several benefits, including improved accuracy in measuring liquid levels, increased operational efficiency, and enhanced safety by preventing overflows or leaks. They are essential in various industries, such as manufacturing, oil and gas, and water treatment.

Applications of Liquid Level Gauges

Liquid level gauges are widely used in industries that require precise monitoring of liquid levels, such as chemical processing plants, refineries, and food production facilities. They are also commonly found in storage tanks, boilers, and underground storage tanks.

Factors to Consider When Choosing a Liquid Level Gauge

When selecting a liquid level gauge, it is essential to consider factors such as the type of liquid being measured, the operating conditions (pressure and temperature), the level of accuracy required, and the installation requirements. Choosing the right gauge ensures reliable and accurate measurements.

Installation and Maintenance of Liquid Level Gauges

Proper installation and regular maintenance are crucial for the effective operation of liquid level gauges. It is essential to follow the manufacturer's instructions for installation and calibration to ensure accurate readings. Routine maintenance helps prevent malfunctions and extends the lifespan of the gauge.

Common Challenges with Liquid Level Gauges

Despite their benefits, liquid level gauges may face challenges such as corrosion, build-up of debris, or mechanical failure. Regular inspection and cleaning can help address these issues and ensure the continued efficiency of the gauges.

Future Trends in Liquid Level Gauging Technology

Advancements in technology have led to the development of smart liquid level gauges that offer remote monitoring capabilities, real-time data visualization, and predictive maintenance features. These innovations improve efficiency and reduce the risk of human error in liquid level measurement.

Regulatory Standards for Liquid Level Gauges

Various regulatory bodies set standards for the design, installation, and operation of liquid level gauges to ensure safety and accuracy. Compliance with these standards is crucial for industries that rely on liquid level gauges for critical processes.

Choosing the Right Liquid Level Gauge for Your Application

Selecting the appropriate liquid level gauge for your specific application depends on factors such as the type of liquid, the range of measurement required, and the environmental conditions. Consulting with a professional or supplier can help you choose the best gauge for your needs.

Quote Inquiry

Contact us!