What is a Low pressure filter and Why is it Important?

A low pressure filter is an essential component in many industrial processes and systems. It is designed to remove impurities and contaminants from liquids or gases while operating at low pressure levels. These filters play a crucial role in ensuring the efficiency, reliability, and longevity of various equipment and machinery.

Enhancing Performance and Efficiency

By incorporating a low pressure filter into your system, you can significantly enhance its performance and efficiency. These filters are designed to capture and remove particles, debris, and contaminants that can clog or damage sensitive components. By preventing these contaminants from reaching critical parts of the system, the filter helps maintain optimal operating conditions and prevents unnecessary downtime.

Protecting Equipment and Machinery

One of the primary purposes of a low pressure filter is to protect equipment and machinery from damage caused by foreign particles. Whether it's a hydraulic system, pneumatic system, or any other fluid-based system, the presence of contaminants can lead to abrasion, wear, and corrosion. By effectively filtering out these impurities, the filter ensures the longevity and reliability of the equipment.

Ensuring Clean and Pure Fluids

In industries such as pharmaceuticals, food and beverage, and electronics, the purity of fluids is of utmost importance. A low pressure filter plays a crucial role in ensuring that the fluids used in these industries are clean and free from any contaminants. This is essential to maintain product quality, adhere to regulatory standards, and prevent any potential health risks associated with contaminated fluids.

Extending the Lifespan of Filters

Low pressure filters themselves require maintenance and occasional replacement. However, by using a low pressure filter in your system, you can actually extend the lifespan of the filters. When contaminants are effectively captured and removed by the low pressure filter, they don't reach the main filter elements, reducing their workload and increasing their overall lifespan.

Improved System Reliability of a Low pressure filter

Reliability is a critical factor in any industrial process or system. A low pressure filter can significantly contribute to the overall reliability of a system by preventing clogging, blockages, and damage to sensitive components. By ensuring a consistent flow of clean fluid or gas, the filter helps maintain optimal performance and avoids costly breakdowns or repairs.

Easy Installation and Maintenance

Low pressure filters are designed to be user-friendly, making installation and maintenance hassle-free. They are typically compact in size and can be easily integrated into existing systems without requiring significant modifications. Regular maintenance involves simple tasks such as replacing filter elements or cleaning the filter housing, ensuring that the filter continues to operate at its best.

Wide Range of Applications

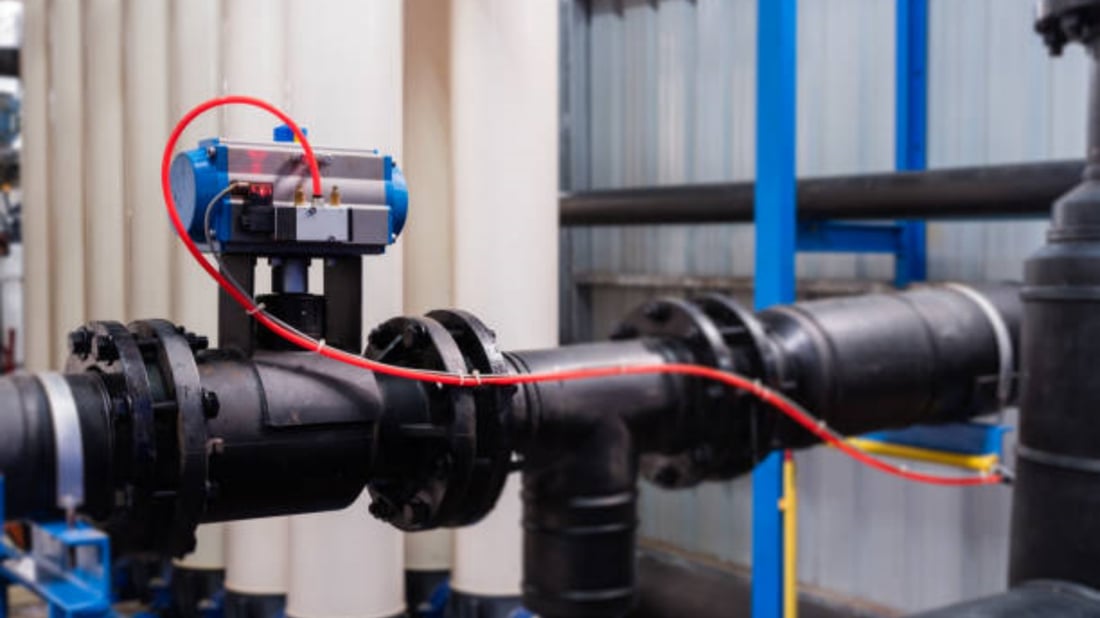

Low pressure filters find applications in various industries and processes. They are commonly used in hydraulic systems, lubrication systems, cooling circuits, pneumatic systems, and many other fluid-based applications. Their versatility and effectiveness make them a vital component in ensuring the smooth operation of diverse equipment and machinery.

Choosing the Right Low Pressure Filter

When selecting a low pressure filter for your specific application, there are several factors to consider. These include the flow rate, pressure rating, filtration efficiency, and compatibility with the fluid or gas being filtered. It is important to consult with experts or manufacturers to ensure you choose the most suitable filter that meets your specific requirements.

Conclusion

A low pressure filter is an indispensable component in many industrial processes and systems. Its primary purpose is to remove contaminants and impurities, ensuring clean and efficient operations. By investing in a high-quality low pressure filter and incorporating it into your system, you can enhance performance, protect equipment, maintain purity, extend filter lifespan, improve reliability, and benefit from its wide range of applications.