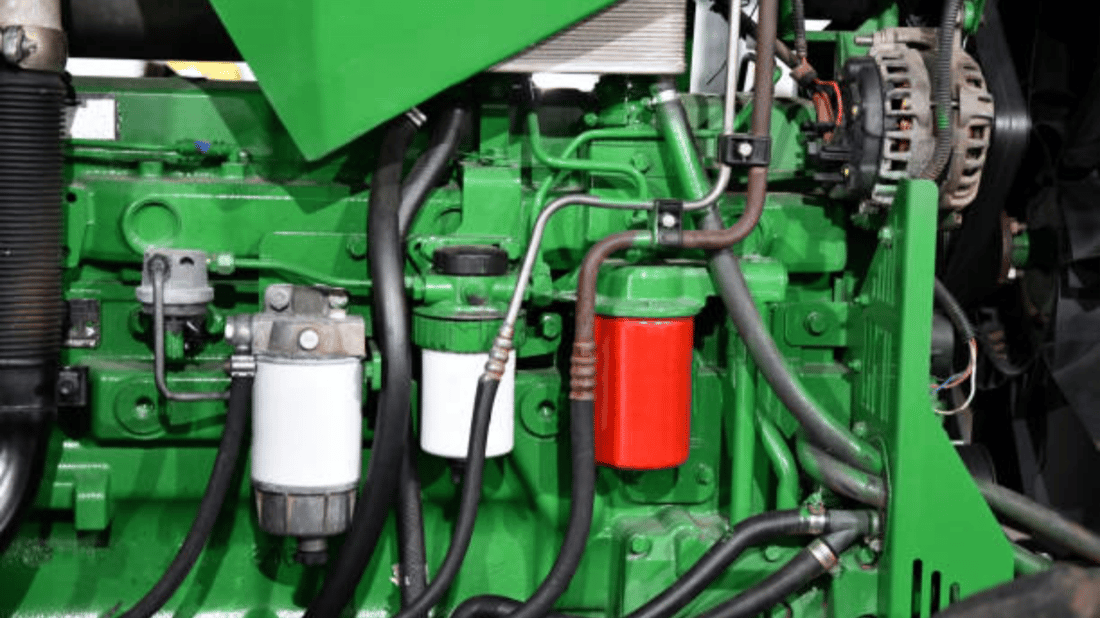

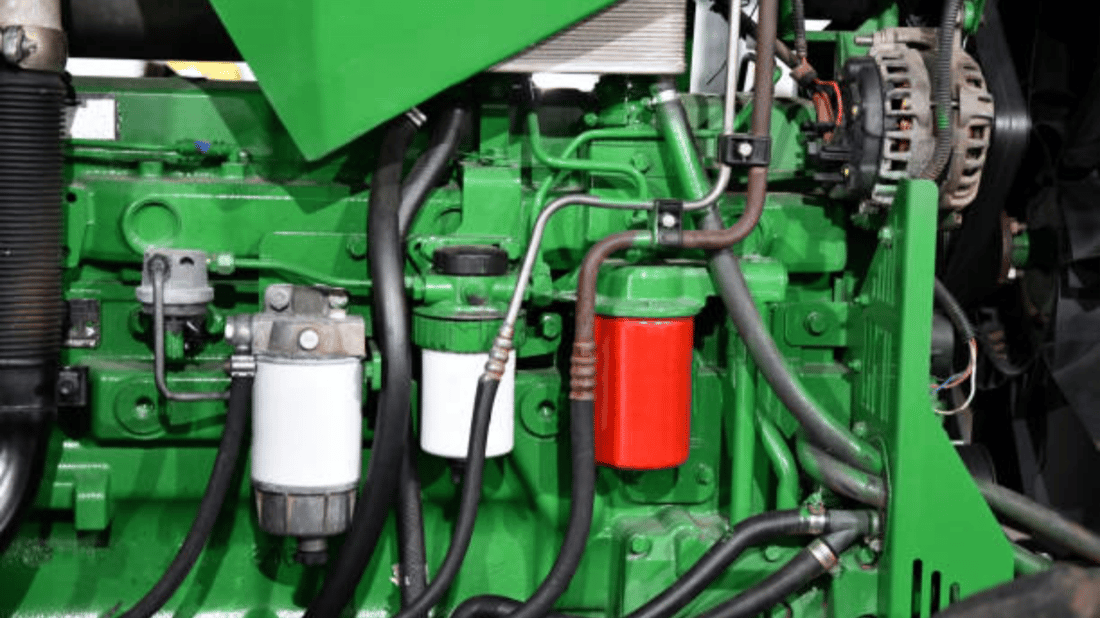

A high pressure inline filter is a crucial component in many industrial and commercial applications. It is designed to remove contaminants and impurities from liquids or gases flowing through a system under high pressure. These filters are commonly used in hydraulic systems, water purification systems, and more.

Importance of Using High Pressure Inline Filters

Using high pressure inline filters can help prevent damage to sensitive equipment and machinery by capturing particles and debris before they can cause issues. By maintaining clean fluid or gas flow, these filters can extend the lifespan of valuable machinery and ensure consistent performance.

How High Pressure Inline Filters Work

High pressure inline filters work by trapping contaminants within the filter media as fluid or gas passes through. The filter media may consist of various materials, such as mesh, screens, or membranes, that are designed to capture particles of a specific size. By understanding the filtration requirements of the system, the right filter media can be chosen for optimal performance.

Types of High Pressure Inline Filters

There are several types of high pressure inline filters available, including cartridge filters, bag filters, and basket strainers. Cartridge filters are popular for their ease of use and replaceability, while bag filters are known for their high dirt-holding capacity. Basket strainers, on the other hand, are ideal for applications where frequent cleaning is necessary.

Benefits of High Pressure Inline Filters

The benefits of using high pressure inline filters extend beyond equipment protection. These filters can also improve system efficiency, reduce maintenance costs, and enhance overall product quality. By investing in high quality filters, businesses can save time and money in the long run.

Choosing the Right High Pressure Inline Filter

When selecting a high pressure inline filter, it is important to consider factors such as flow rate, pressure rating, filtration efficiency, and compatibility with the fluid or gas being filtered. Consulting with a knowledgeable supplier can help ensure that the right filter is chosen for the specific application.

Maintenance and Cleaning of High Pressure Inline Filters

Regular maintenance and cleaning of high pressure inline filters is essential for optimal performance. Depending on the type of filter used, cleaning may involve replacing filter cartridges or bags, or cleaning out strainer baskets. By following recommended maintenance schedules, the lifespan of the filter can be prolonged.

Applications of High Pressure Inline Filters

High pressure inline filters are used in a wide range of industries, including manufacturing, automotive, aerospace, and food and beverage. They are essential for maintaining clean and contaminant-free fluid or gas flow in critical systems, ensuring smooth operation and preventing costly downtime.

Installation and Integration of High Pressure Inline Filters

Proper installation and integration of high pressure inline filters is key to their effectiveness. Filters should be installed in the correct orientation and location within the system to maximize filtration efficiency. Additionally, regular monitoring of filter performance is important to detect any issues early on.

Conclusion

In conclusion, high pressure inline filters play a vital role in maintaining system efficiency, protecting equipment, and ensuring product quality. By understanding the importance of these filters and selecting the right type for specific applications, businesses can benefit from improved performance and cost savings in the long term.

Quote Inquiry

Contact us!