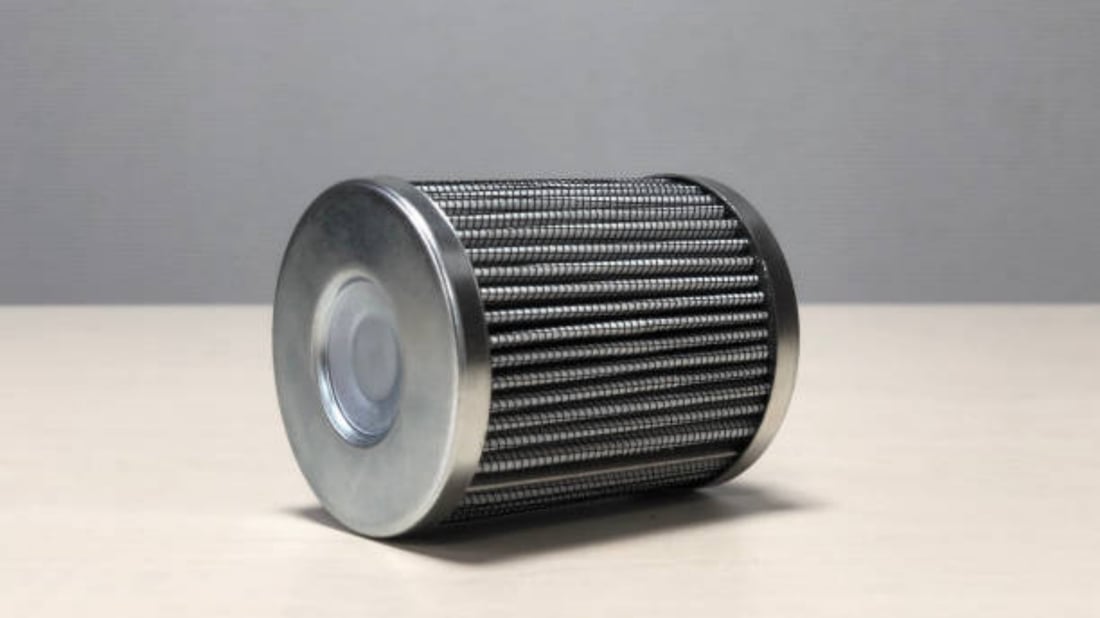

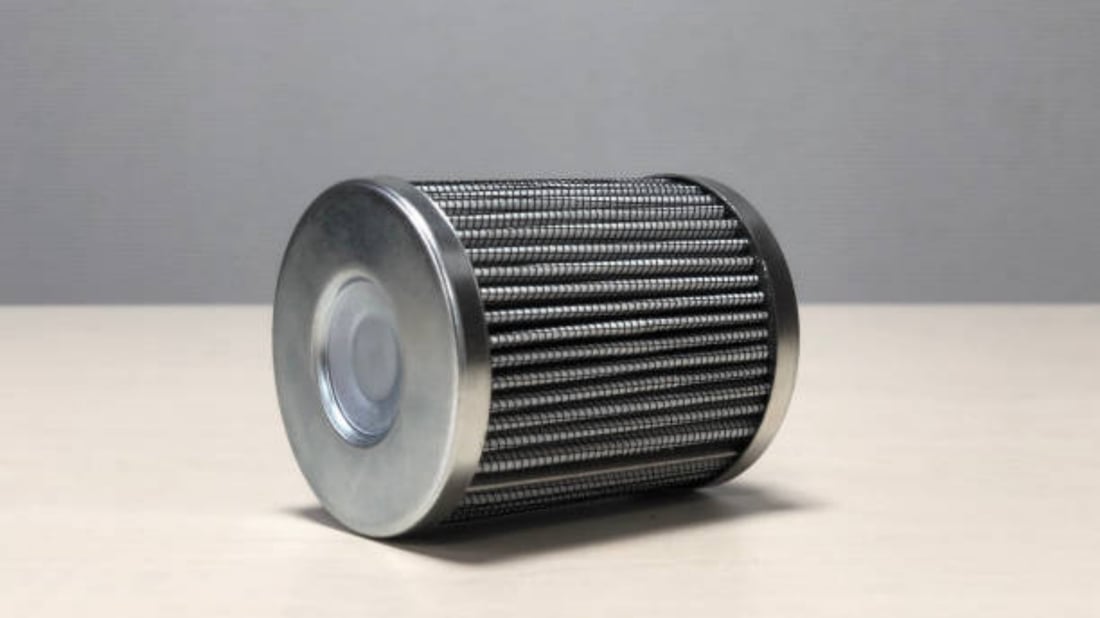

Stainless steel filters are widely used in various industries due to their durability and resistance to corrosion. Proper stainless steel filter maintenance is crucial to ensure the longevity and efficiency of these filters. Neglecting maintenance can lead to clogging, reduced filtration capability, and increased operational costs. Regular upkeep preserves filter performance and protects downstream equipment.

Routine Cleaning Techniques for Stainless Steel Filters

Cleaning is a fundamental aspect of stainless steel filter maintenance. Common methods include backflushing, ultrasonic cleaning, and chemical soaking, depending on the type of contaminants and filter design. Effective cleaning removes trapped particles and residues, restoring optimal flow rates and filtration quality. Selecting the right cleaning method extends filter life and maintains system efficiency.

Inspection Practices to Detect Wear and Damage Early

Routine inspections play a key role in stainless steel filter maintenance by identifying signs of wear, corrosion, or physical damage before they worsen. Visual checks combined with non-destructive testing methods help detect cracks, deformation, or pitting. Early detection allows for timely repairs or replacements, preventing costly downtime and ensuring continuous operation.

Impact of Operating Conditions on Filter Longevity

Operating conditions such as temperature, pressure, and chemical exposure significantly influence stainless steel filter maintenance needs. Filters exposed to extreme environments might require more frequent cleaning and inspection. Understanding these factors allows for tailored maintenance schedules, helping maintain filter integrity under demanding conditions.

Filter Element Replacement: When and How

Despite regular maintenance, stainless steel filter elements eventually reach the end of their service life. Knowing the signs indicating replacement—such as persistent clogging, compromised structure, or reduced filtration efficiency—is essential. Proper replacement procedures help avoid contamination risks and maintain the filtration system's overall reliability.

Preventive Maintenance Strategies for Stainless Steel Filters

Implementing preventive maintenance strategies optimizes stainless steel filter performance and minimizes unexpected failures. This includes scheduled cleaning, monitoring pressure differentials, and keeping maintenance logs. Proactive measures help extend the filter’s lifespan, reduce energy consumption, and improve system uptime.

Role of Lubricants and Protective Coatings in Filter Care

Applying lubricants to moving parts or protective coatings to exposed surfaces can enhance stainless steel filter durability. Such treatments reduce friction, prevent corrosion, and facilitate easier cleaning during maintenance. Selecting compatible products ensures chemical resistance without compromising the filter’s material integrity.

Environmental and Safety Considerations During Maintenance

Stainless steel filter maintenance must consider environmental and safety factors, especially when using chemical cleaners or disposing of waste materials. Proper handling, using environmentally friendly agents, and adhering to safety protocols protect workers and minimize ecological impact. Following these guidelines also ensures regulatory compliance.

Common Challenges in Stainless Steel Filter Maintenance

Challenges such as hardened deposits, microbial growth, or mechanical damage can complicate stainless steel filter maintenance. Addressing these issues may require specialized cleaning agents, equipment adjustments, or filter redesign. Understanding common obstacles helps develop more effective maintenance approaches and avoid recurrent problems.

Technological Innovations Improving Filter Maintenance

Advancements such as automated cleaning systems, real-time monitoring sensors, and improved filter materials have revolutionized stainless steel filter maintenance. These technologies enable more precise maintenance scheduling, reduce manual labor, and enhance filter durability. Staying updated on such innovations can provide operational advantages and cost savings.

Quote Inquiry

contact us