Industrial tank monitoring is a vital process that involves continuously assessing the conditions of storage tanks used across various industries, including oil and gas, chemical manufacturing, and water treatment. This monitoring ensures the safety, efficiency, and longevity of tanks by tracking parameters such as fluid levels, temperature, pressure, and structural integrity. Effective industrial tank monitoring helps prevent leaks, spills, and catastrophic failures, safeguarding both the environment and industrial assets.

Types of Sensors Used in Industrial Tank Monitoring

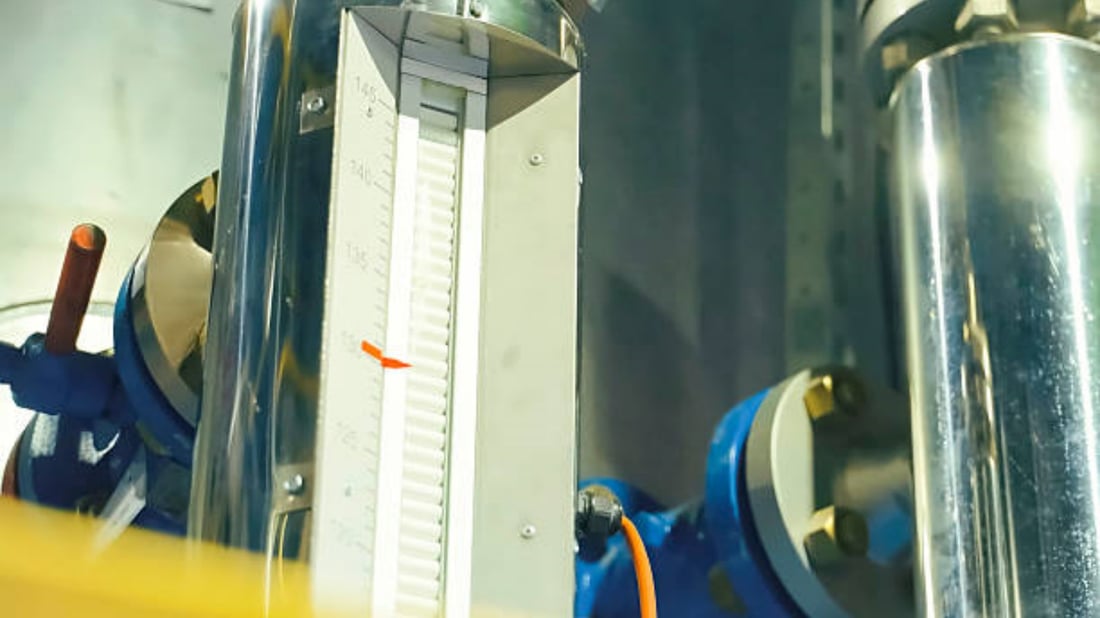

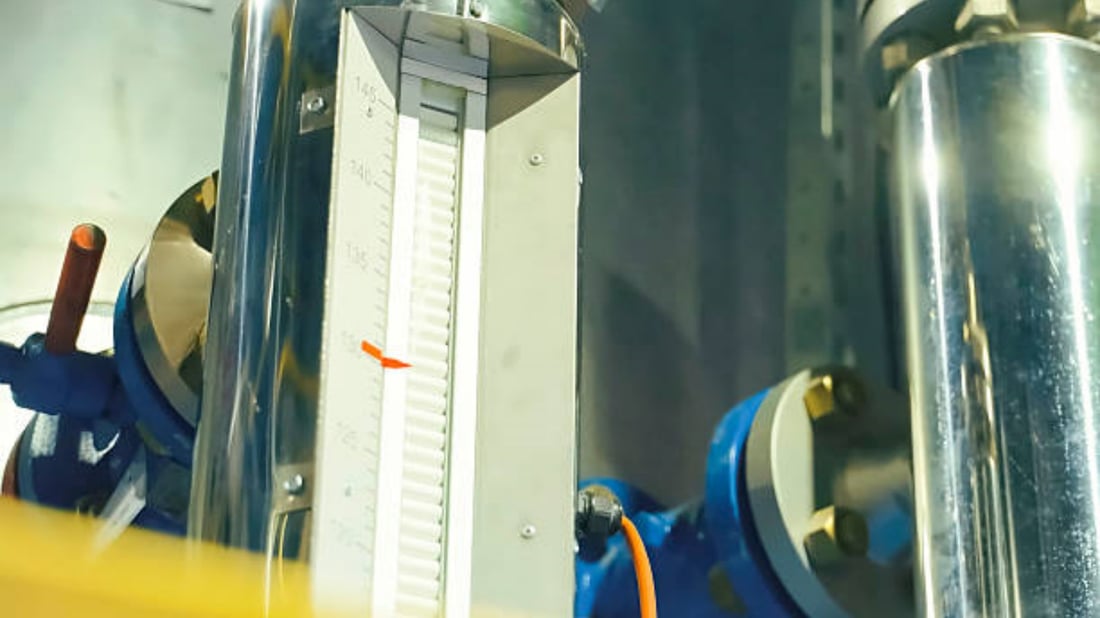

A key aspect of industrial tank monitoring lies in the selection and deployment of sensors. Commonly used sensors include ultrasonic level sensors, radar sensors, pressure transducers, and temperature probes. Ultrasonic and radar sensors are particularly favored for non-contact level measurement, providing accurate readings without exposing equipment to harsh chemicals or extreme conditions. The adoption of wireless sensor networks has further enhanced real-time data acquisition and analysis.

Benefits of Real-Time Data Collection in Industrial Tank Monitoring

Real-time data collection in industrial tank monitoring allows operators to make informed decisions promptly, preventing overflows, material shortages, or safety hazards. Continuous monitoring provides insights into tank conditions, enabling predictive maintenance and reducing downtime. Additionally, real-time alerts contribute to regulatory compliance by ensuring that tanks operate within safe parameters at all times, minimizing the risk of environmental contamination.

Role of IoT in Modern Industrial Tank Monitoring Solutions

The integration of the Internet of Things (IoT) technology has revolutionized industrial tank monitoring by enabling remote access and control over tank systems. IoT devices collect data from sensors and transmit it to cloud platforms, where advanced analytics help predict maintenance needs and optimize inventory management. This connectivity also facilitates seamless integration with broader industrial automation systems, creating smarter and more responsive operations.

Ensuring Compliance with Industry Standards Through Monitoring

Industrial tank monitoring is essential for regulatory compliance in sectors where storing hazardous or volatile substances is common. Monitoring systems help companies adhere to standards set by environmental agencies and safety organizations by providing documentation of tank conditions and immediate alerts if parameters exceed legal limits. This compliance reduces legal risks and enhances corporate responsibility.

Preventative Maintenance Strategies Enabled by Tank Monitoring

Industrial tank monitoring paves the way for preventative maintenance strategies by identifying early signs of wear, corrosion, or sensor inaccuracies. Continuous data analysis enables maintenance teams to schedule repairs before failures occur, extending tank lifespan and avoiding costly emergency interventions. This approach promotes operational continuity and cost efficiency.

Environmental Impact Reduction Through Effective Tank Monitoring

Proper industrial tank monitoring significantly reduces environmental impact by preventing leaks and chemical spills. Early detection of anomalies allows operators to act swiftly, minimizing soil and water contamination. In industries with stringent environmental controls, such monitoring not only protects ecosystems but also maintains brand reputation and community trust.

Challenges and Limitations in Industrial Tank Monitoring Systems

Despite numerous advantages, industrial tank monitoring faces challenges such as sensor fouling, signal interference, and the need for calibration in harsh environments. Additionally, integrating legacy tank systems with modern monitoring solutions can be complex and costly. Addressing these limitations requires ongoing innovation in sensor technology and system design.

Case Studies Demonstrating the Effectiveness of Industrial Tank Monitoring

Numerous case studies highlight the success of industrial tank monitoring across industries. For example, oil refineries employing real-time level sensors have reported significant reductions in spill incidents and downtime. Chemical plants using IoT-enabled monitoring have optimized inventory management, reducing waste and improving safety protocols, demonstrating the tangible business benefits of these systems.

The Future of Industrial Tank Monitoring: Innovations on the Horizon

The future of industrial tank monitoring is driven by advancements such as artificial intelligence (AI), machine learning, and enhanced sensor materials. AI-powered analytics will enable predictive insights with greater accuracy, while new sensor designs will improve durability and reduce maintenance. Moreover, increased adoption of wireless and edge computing technologies will empower more flexible and scalable monitoring solutions.

Quote Inquiry

contact us