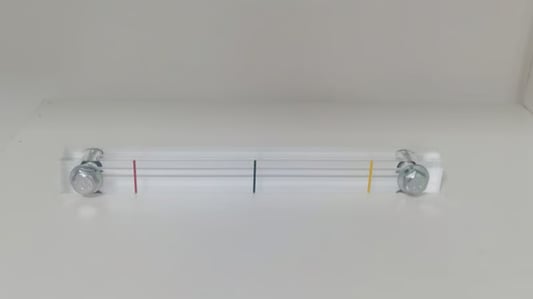

What is a hydraulic oil filter?As its name suggests, a hydraulic oil filter is a device used to remove impurities and contaminants from hydraulic oil. Hydraulic systems in machinery rely on clean, filtered oil to function properly and efficiently. The filter traps debris such as dirt, metal particles, and other contaminants that can damage the system if not removed.Benefits of Using Hydraulic Oil FiltersUsing hydraulic oil filters in machinery maintenance has numerous benefits. Filters help extend the life of hydraulic components by preventing wear and tear caused by contaminants. Clean oil also improves the overall efficiency of the hydraulic system and reduces the risk of costly repairs and downtime.Types of Hydraulic Oil FiltersThere are several types of hydraulic oil filters available on the market, including suction strainers, inline filters, and return line filters. Each type is designed to meet specific filtration requirements based on the machinery's hydraulic system and operating conditions.How Hydraulic Oil Filters WorkHydraulic oil filters work by capturing contaminants as the oil flows through the filter media. The filter media can be made of materials such as cellulose, synthetic fibers, or metal mesh, depending on the level of filtration required. As the oil passes through the filter, particles are trapped, allowing only clean oil to flow back into the system.Replacing Hydraulic Oil FiltersRegularly replacing hydraulic oil filters is essential for maintaining the efficiency and performance of machinery. Over time, filters become clogged with contaminants and lose their effectiveness. By following the manufacturer's recommendations for filter replacement intervals, operators can ensure the hydraulic system continues to operate smoothly.Choosing the Right Hydraulic Oil FilterWhen selecting a hydraulic oil filter for a specific machinery application, factors such as flow rate, pressure rating, and compatibility with hydraulic fluids should be considered. It is crucial to choose a filter that meets the system's requirements to ensure optimal performance and longevity.Common Signs of a Clogged FilterOne of the indications of a clogged hydraulic oil filter is a decrease in system performance. Machinery may experience sluggish operation, increased noise, or overheating due to restricted oil flow. Regular monitoring and inspection of filters can help prevent these problems.The Role of Filtration in Preventative MaintenanceFiltration is a critical aspect of preventative maintenance for hydraulic systems. By regularly changing filters and monitoring oil quality, operators can avoid costly repairs and downtime. Proper filtration also helps extend the life of hydraulic components and ensures reliable machinery operation.Importance of Quality Filters in Hydraulic SystemsInvesting in high-quality hydraulic oil filters is crucial for maintaining the integrity and performance of hydraulic systems. Cheap or inferior filters may not effectively remove contaminants, leading to increased wear on components and potential system failures. Quality filters offer superior filtration and protection for machinery.ConclusionIn conclusion, hydraulic oil filters play a vital role in maintaining the efficiency and longevity of hydraulic systems in machinery. Regularly replacing filters, choosing the right filter for the application, and monitoring filter performance are essential aspects of machinery maintenance. By prioritizing filtration, operators can ensure the smooth operation of hydraulic systems and minimize the risk of costly repairs.Quote Inquirycontact us